PRINTED ELECTRONICS

THE FLEXIBLE FUTURE

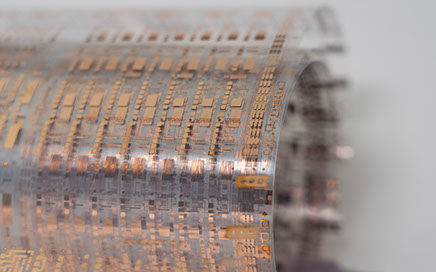

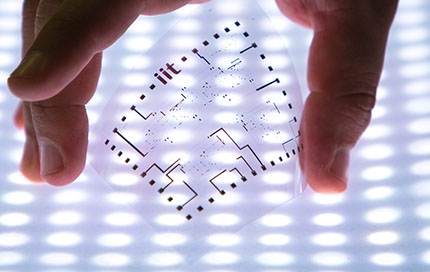

Printed electronics describes the combination of conductive materials as well as lacquer and paint systems that are transferred in several layers to large areas and cost-effectively on foils, paper and other flexible carriers.

Printed electronics offers a wide range of applications and is the key to high-volume production

FIELDS OF APPLICATION PRINTED ELECTRONICS

The rise of printed electronics is inevitable – flexible displays, battery technology or standard electronics.

Printed and flexible electronics enable a wide range of applications and low manufacturing costs, for example for the production of sensors or battery technology.

RFID

PRESSURE SENSORS

Sensors that simultaneously recognize the shape, size and pressure of objects on them are becoming increasingly standard in smart products.

BATTERY TECHNOLOGY

CELL PRODUCTION

Printed batteries represent a cost-effective alternative to conventional batteries and button cells.

TEMPERATURE

SENSORS

WEARABLES

MEDICAL & CONSUMER

MEDICAL TECHNOLOGY

Above all, their flexibility makes printed and organic electronics interesting for medicine.

SENSORS

The research institute ID-Tech-Ex predicts that the market for printed and flexible sensors will grow to 7 billion US dollars by 2020.

INTELLIGENT

PACKAGINGS

Interactive elements and the linking of online and offline reality open up new dimensions in advertising for mass products.

SHIPPING

TRACKING

MICROELECTRONICS

PRINTING INDUSTRY

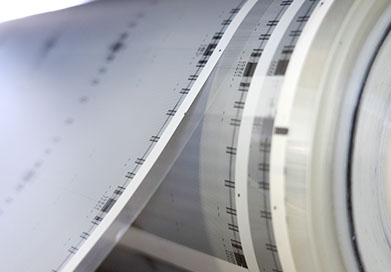

REEL TO REEL

PRINTER LINES

Almost all applications of printed electronics can be produced with our lines and extremely efficiently in the reel to reel process.

ACCELERATE

YOUR PRODUCTION.

Benefit from our experience and find out how to improve your production efficiency with printed electronics.