INTERNAL

MEASUREMENT

LABORATORY

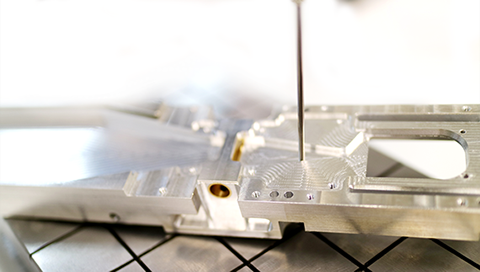

We check the products with the latest software in Calypso. Depending on the components, this can be done with tactile measuring systems or linked to non-contact measurement with optics and lasers as well as contour and roughness measuring devices.

ZEISS SYSTEMS

SET-UP

Highest precision must be verified. We rely on our Zeiss Set-Up to get full documentation on every part that leaves the production.

We are working according ISO GPS 8015

QUALITY MANAGEMENT

DIN EN ISO 9001-2015

- Initial sample test report

- Series and special measurement of workpieces

- Ability study including statistical evaluation

- Job programming

- D target/actual comparison

- Measurement against data set / target data

Quality-related project support

Non-contact measurement with optics + laser

MEASUREMENT LABORATORY

SERVICES

- Measurement reports according to VDA / PPAP or on any form are a matter of course for us

- Measurement system analysis according to PUMA / GOM.

- Deviation calculation and determination of the correction data for component analyzes in the field of material testing and defect analysis.

- Re-qualification measurements

- Measurements accompanying the series

FULL PROCESS INTEGRATION

Starting with the first sketch and ending with a complete product. That is what happens within our factory. Wether we produce parts for our own assembly lines or mill a single piece for a client; the measuring department is always part of the process to ensure quality and precision.

ZEISS O-INSPECT

In addition to the tactile systems we also use a Zeiss optical inspection unit.

Zeiss Calypso

The whole measuring department works with the latest Calypso software and is fully integrated in our digital workflow.